Article No. 529001

Water-based, hard-wearing 1K sealant based on renewable raw materials for two-time application

Product specifications

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Interior wood

- Exterior wood not directly exposed to weather

- Furniture and interior finishing work

- Wooden floors and stairs

- An alternative to products with a high solvent content for wooden flooring as per TRGS 617

- Tables and worktops

- Primer: minimisation of swelling behaviour (opaque structures)

- Terrace furniture in sheltered outdoor areas

- Dimensionally stable wood building elements in sheltered locations

- Sustainable building suitable for building certifications DGnB, LEED, BNB, QNG etc.

- Not for bleached wood

- "Natural look" colour only for light-coloured woods, such as oak, ash and spruce

- No removal of excess

Properties

- Very fast drying

- Resistant to abrasion and scratches

- Resistant to chemicals: DIN 68861, 1B

- Slip-resistant

- Water repellent

- Very low tendency to shine

- Natural look and feel

- Based on renewable raw materials

- Vegan - no additives of animal origin

- VOC-free and low odour

- No creaking

- 2K-ready: increased resistance to chemicals, hand creams, scratches and abrasions by adding 2% Aqua VGA-485

- Fire behaviour according to DIN EN 13501-1: B-s1,d0 on suitable substrates

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Wood moisture content: 8-12%

Softwoods: raw wood longitudinal sanding with P 120

Hardwoods: raw wood longitudinal sanding with P 180

Ring-porous woods (e.g. oak, ash, walnut): additionally brush out pores with a bronze brush

-

Preparations

Thoroughly remove any dirt, grease and non-adhering old coatings.

Wash off greasy or resin-rich woods/substrates with WV-891 or V-890. Use UN-894 indoors on the construction site. Ensure good ventilation for solvents.

Use a stain for tinting if required.

When sealing wooden floors, we recommend pre-treatment with HSO-118 [eco] followed by a drying time of at least 48 hours to ensure saturation and uniform material absorption of the substrate.

Wood in outdoor areas not directly exposed to weathering: Observe BFS Leaflet No. 18 "Coatings on wood and wood-based materials in outdoor areas".

-

-

Application

-

Stir well.

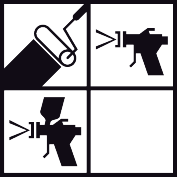

For better wetting of the substrate and pores, we recommend applying the first coat with a roller.

Roller application:

Clear only.

Apply even layer thicknesses, including in overlapping areas.

Application on small areas: microfibre roller, 5 mm pile height.

Application on large areas: microfibre roller, 8 mm pile height.

Spray application:

Flow cup gun: nozzle size: 1.0 - 1.6 mm, atomiser air pressure: 1.0 - 2.0 bar.

Airless spraying: nozzle size: 0.23 mm, material pressure: 60 - 80 bar.

Airmix spraying: nozzle size: 0.23 mm, material pressure: 50 - 70 bar, atomiser air pressure: max. 1 bar.

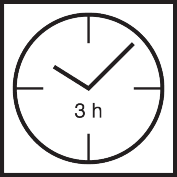

After drying and intermediate sanding (P 240 - 320), apply a second coat of the product.

Observe the waiting times between coats.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

For optimal chemical resistance on porous woods in areas subject to higher levels of stress, the first coat should be applied using a roller or brush to ensure that the pores are wetted and saturated.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

Prior to full application, please apply a test coat to a sample area under practical conditions using the desired system, then test or examine the surface properties.

This product is marketed as a "no creaking" product when used on staircases. This is only possible if the stairs have been constructed correctly and professionally (design, accuracy of fit, wood moisture content).

For smoked oak and other exotic woods, Remmers Technical Service must be consulted prior to use and a trial area set up.

*Information about self-ignition

In external tests, the tested product exhibited significantly lower reactivity than conventional reference products that dry by oxidation. The risk of self-ignition is therefore classified as lower.

It should be noted that the tests carried out by EPH could not take into account all possible scenarios that might occur in practice. For example, contact of objects and media contaminated with this product, such as rags or dust, with other highly flammable agents, such as dust containing cellulose nitrate or certain solvents, could lead to conditions that result in ignition.

Avoid excessive overspray.

Leave fresh spray mist to dry for at least 48 hours before sweeping up.

Collect spray mist in fireproof waste containers and spray regularly with water to prevent self-ignition of the spray mist, especially if large quantities accumulate.

-

Drying

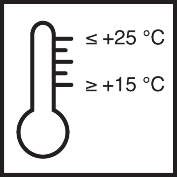

Practice values at +20 °C and 65% relative humidity.

Low temperatures and high humidity delay drying.

Drying is dependent on the type of wood and the absorbency of the substrate.

-

Working tools / cleaning

-

Sealant roller with microfibre cover approx. 5 - 8 mm pile height, flow cup gun, airless/airmix spraying equipment

Clean tools with water or Aqua RK-898 Cleaning Concentrate immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

Two coats at 70 - 90 ml/m² per coat

-

General information

-

DIN EN 71-3 "Migration of certain elements":

This product complies with the limits for the migration of heavy metals to children's toys according to DIN EN 71-3 and thus fulfils one of several further requirements for the safety of children's toys according to the EU "Toy Directive" (2009/48/EC).The variant "grain+" initially creates subtle emphasis of the grain. Over time, a warm colour tone generally intensifies.

Oil-based products contain natural ingredients. Under the influence of UV light, exclusion of light (dark yellowing), heat or individual changes in the wood, these can lead to a change in the surface. Please refer to the information sheet on general application instructions for oils and waxes. White, pastel and grey tones can lose their intensity within a short period of time. This happens depending on the type of wood used, substances contained in the wood, exposure to light and heat. If these changes are not desired, a stained and lightfast lacquered surface finish using a water-based, lightfast stain is recommended.

Use breathable materials when packing the coated wood building elements.

When applying over large surface areas in the commercial flooring sector, consult Remmers Technical Service in advance and create a trial area.

Assessment of sealed wooden floors according to DIN 18356 (permissible unevenness under grazing light incidence).

Dust and loose dirt on stairs should be removed regularly using a soft broom or mop.

For overhauls and top-ups, we recommend using Oiled Floor Care [eco].

Oiled French doors and exterior doors do not meet the standards for the coating of dimensionally stable wood building elements

The maintenance and care kit can be used for top-ups and long-term preservation of surfaces.

Observe the "Care instructions for surfaces and floors treated with oil or hard wax sealers".

Please refer to the relevant test reports/certificates and the Technical Data Sheet for information on certified products and configurations.

Additional information on use:

Estimate the amount needed in order to reduce material waste.

Keep any unused product for later use.

Reusing the product can effectively reduce its environmental impact over its life cycle.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![Aqua HWS-712 [eco] Aqua HWS-712 [eco]](https://m.remmers.com/gebindeabbildungen/2400w/179294.png?w=100&version=2)