Article No. 091611

Special, substrate-tolerant primer

Product specifications

Component A

Component B

Mixture

Once fully cured

* Epoxy resin mortar 1 : 10 with Selectmix RMS

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Primer, bonding layer on difficult substrates, e.g. tiles and various metals

- Levelling layer

- Producing compression-resistant mortars, flow coatings

- Base layer for blinded covers

- Production of pressure-resistant mortar for height levelling, for use as repair mortar and as epoxy screed in composites and on separating layers

Properties

- Excellent adhesion on many substrates

- Suitable on oily substrates or ones with residual moisture

- Can be subjected to mechanical loads

- High compressive strength and flexural strength

- Physiologically harmless once fully cured

- Suitable for use as primer without broadcasting underneath Remmers PU and EP coatings

- Designed for the use of non-dried screed sand

- Economically efficient thanks to high degree of filling

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

The tensile strength of the surface of the substrate must be at least 1.5 N/mm² on average (smallest individual value of at least 1.0 N/mm²), and the compressive strength must be at least 25 N/mm².

The substrate can be slightly moist but without liquid film on the surface and should not be exposed to major temperature swings (vapour pressure). In this case the primer must always be applied twice.

Concrete max. 6 m% moisture Cement screed max. 6 m% moisture The substrate must be protected from exposure to moisture from underneath during utilisation.

The suitability of the coating on steel, stainless steel, aluminium, ceramic covers must be tested beforehand, if necessary trial surfaces must be set up.

-

Preparations

Prepare the substrate by suitable means, e.g. steel ball jetting or diamond grinding, so that it meets the requirements specified above.

Broken-out or missing areas in the substrate should be filled flush with the surface using Remmers RM systems (RM = Repair Mortar) or Remmers EP mortars.

Bonded screed:

Prime the surface with a suitable primer, such as Remmers Epoxy ST 100, and broadcast it generously with Quartz 07/12 (approx. 2 kg/m²).

Alternatively, it is possible to work wet-on-wet.

Pour the material onto the prepared surface and spread using a suitable tool, e.g. a notched trowel.

Screed on separation layer/insulating layer:

The separation layer/insulation layer must be suitable for the use in question. In this application case, no primer is needed.

The current technical regulations must be observed.

-

-

Preparation

-

Combination container

Add the entire quantity of the hardener (component B) to the base compound (component A).

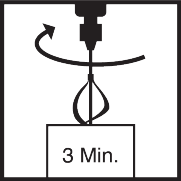

Mix thoroughly with a slow-speed electric mixer

(approx. 300 - 400 rpm).Pour the mixture into a separate container and mix again thoroughly.

Mix for at least 3 minutes.

Insufficient mixing is indicated by streaks forming.

-

Application

-

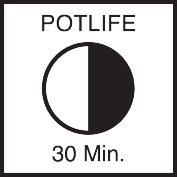

As a general principle, higher temperatures will reduce and lower temperatures will increase the times stated.

-

Working tools / cleaning

-

Smoothing trowel, toothed trowel, toothed squeegee, rubber squeegee, epoxy roller, spiked roller, mixing equipment, if necessary a positive mixer.

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and splashed material immediately while fresh with V 101.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

See application examples

-

-

Application examples

-

P

Apply the mixed resin generously to the surface. Distribute with a suitable tool, e.g. rubber blade, and work into the substrate with an epoxy roller so that pores in the surface of the substrate are completely filled.

Approx. 0.30 - 0.50 kg/m² of binder (depending on the substrate)

-

LLRC

Apply the filled material (up to 1 : 1 parts by weight) to the primed surface and distribute with a suitable trowel. If necessary, roll over with a spiked roller.

Per mm of base layer thickness:

approx. 0.85 kg/m² of binder

and 0.85 kg/m² of Selectmix 01/03 -

EM

Spread and smooth out the filled material (up to 1 : 10 parts by weight) with a smoothing trowel.

Bonded screed from 10 mm: After the material has been mixed with filler in a ratio of up to 1:20 parts per weight, distribute it and level it off, then compact and work the material by smoothing until an even surface is achieved.

Screed on separation layer/insulation layer > 30 mm: After the material has been mixed with filler in a ratio of up to 1:25 parts per weight, distribute it and level it off, then compact and work the material by smoothing until an even surface is achieved.

Per mm of layer thickness: approx. 0.2 kg/m² of binder

and 2.0 kg/m² of Selectmix RMS

Bonded screed from 10 mm:

Per mm of layer thickness: approx. 0.1 kg/m² of binder

and 2.0 kg/m² of suitable filler

Screed on separation layer/insulating layer > 30 mm:

Per mm of layer thickness: approx. 0.1 kg/m² of binder

and approx. 2.0 kg/m² of suitable filler -

BLFSL

Apply the filled material (up to 1 : 1 parts by weight) to the primed surface and distribute with a suitable toothed trowel or toothed rubber blade. If necessary, roll over with a spiked roller.

Liberally broadcast fire-dried quartz sand over the base layer while it is still fresh.

Remove any loose, excess material after hardening.

Per mm of base layer thickness:

approx. 0.85 kg/m² of binder

and 0.85 kg/m² of Selectmix 01/03

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C). Slight deviations from these values may arise if the product is worked with on site.

Primers must always be applied so that all pores are filled; it may therefore be necessary to increase the application rate or to apply a second coat.

Abrasive mechanical loads leave traces of wear.

Epoxy resins are generally not colourfast when exposed to UV light or weather.

Further notes on working, system construction and maintenance of the listed products can be found in the latest Technical Data Sheets and the Remmers system recommendations.

The compressive and flexural strength of the screed on separation layers/insulating layers are highly dependent on the proportion of filler and binder used. Adapt these proportions according to the application at hand.

The worksheet BEB KH 505 from the German Federal Association of Screed and Floor Covering must be observed.

When using a wet filler (e.g. moistened Selectmix RMS or screed sand), the screed must have reached its equilibrium moisture or must be completely dry before the coating or covering is applied.

Covering the surface (e.g. with foil) significantly extends the time it takes for the material to be ready to be covered.

When using screed sand, the working properties and the strengths that can be achieved are highly dependent on the specific composition of the local screed sand and must be tested in advance.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For professional users only!

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-