Article No. 106425

Swellable, high-strength grout

Product specifications

7 days: > 85 N/mm²

28 days: > 95 N/mm²

90 days: > 110 N/mm²

after 30 min: ≥ 700 mm

after 60 min: ≥ 650 mm

after 90 min: ≥ 650 mm

(* Flow time for the slump calculation = 150 seconds)

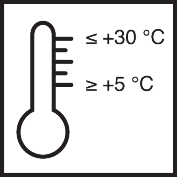

C (at 5°C)

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Interior and exterior use

- Mineral substrates in dry, damp, wet and underwater areas

- Casting and underfilling of machines, steel constructions, train tracks, wind turbines and bridge bearings

- Filling joints between precast units, pre-fab elements and basement slabs

- Embedding supports in concrete in sleeve foundations

- Small-scale concrete repairs

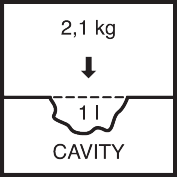

- For filling large cavities in concrete elements in accordance with the third amendment to the guidelines on the protection and repair of concrete structures (Rili-SIB)

Properties

- High early and final strength

- Swelling capable

- Water impermeable

- Corrosion-inhibiting

- Maximum grain size: 3 mm

- Compressive strength after 28 d: ≥ 95 N/mm²

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Pre-wet the substrate so that it is slightly moist.

Expose the grains close to the surface.

The substrate must have an average pull-off strength of at least 1.5 N/mm²

-

-

Application

-

Construct formwork if necessary.

Pour continuously from one side or corner.

Re-compact if necessary.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

Protect wet mortar surfaces against frost, rain and drying out too quickly for at least 4 days.

-

-

Working tools / cleaning

-

Mixer: double-shaft mixer, compulsory mixer

If using a mixing pump, use a batch mixer.Clean tools with water while the material is still fresh.

-

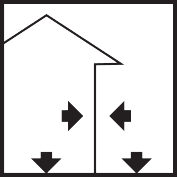

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

Approx. 2.1 kg/dm³

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

The mixing water must be of drinking water quality.

Low chromate content in accordance with Directive 2003/53/EC.

The characteristic data given for the product was determined under laboratory conditions in accordance with DAfStb Guideline - VeBMR.

Alkaline binders may cause a dissolution process on non-ferrous metals.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-