Article No. 345001

Adhesive primer for metals, hard plastics and wood, with rust protection, seals off substances in the wood

Product specifications

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Interior and exterior use

- Primer and intermediate coat

- Metal substrates, e.g. (galvanised) steel, pure aluminium, copper, brass

- Hard plastics: hard PVC, PUR, polyester, acrylic and melamine resin coatings (HPL/CPL)

- Stable old coatings such as alkyd, acrylate, powder coatings and PUR lacquers

- Dimensionally stable wood building elements: e.g. windows and doors

- Wood building elements with limited dimensional stability, e.g. folding shutters, matchboarding, summerhouses

- Wood building elements with no dimensional stability: e.g. fences, framework, carports, planking

Properties

- Water-based

- Very good adhesion to the substrate

- Protects against corrosion

- Reduces yellow stains caused by water soluble substances in the wood when light shades of finishing coat are used

- Low solvent, mild odour

- Weatherproof and moisture-regulating

-

Preparation

-

Substrate requirements

Dimensionally stable wood building elements: wood moisture content 11-15%

Wood building elements with limited or no dimensional stability: wood moisture content max. 18%

-

Preparations

Thoroughly remove any dirt, grease and non-adhering old coatings.

Wood substrates:

Sand planed wood surfaces carefully before applying the first coat in order to ensure good adhesion. Remove all sanding dust.

Sand grey and weathered wood surfaces down to sound, bright wood.

Remove loose and torn knots as well as resin that bleeds and clean with a suitable product (e.g. Remmers thinner & brush cleaner).

Exterior wood that needs to be protected against soft rot and blue stain must be pre-treated with a suitable wood preservative* (*Use biocides safely. Always read the label and product information before use).

Observe BFS Code of Practice No. 18 "Coatings on Wood and Wooden Working Materials in Outdoor Areas".

Iron, steel:

Derust thoroughly. Remove scale layers and rolling skin (derust manually to SA 3 standard of cleanliness). The best results are achieved if the substrate has been sand blasted to SA 2.5 standard of cleanliness (DIN EN ISO 12944-4).

Zinc (galvanised steel):

Clean with an ammonium-based wetting agent, using an abrasive pad. Observe BFS Code of Practice No. 5.

Aluminium (not anodised):

Apply an ammoniacal wetting agent using an abrasive pad, or clean with Remmers Thinner & Brush Cleaner or a cleaning agent containing phosphoric acid. Observe the instructions of BFS Code of Practice No. 6.

Plastics:

Treat rigid PVC, PUR, polyester, acrylic and melamine resin coatings (HPL/CPL) with Remmers Thinner & Brush Cleaner and a non-woven abrasive.

-

-

Application

-

Stir well.

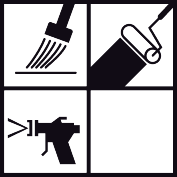

Apply with a brush, roller or by spraying.

Airmix spraying: nozzle 0.28 - 0.33 mm, material pressure: 100 - 140 bar,

atomiser air pressure: 1.2 - 2 bar.Airless spraying: nozzle: 0.28 - 0.33 mm, material pressure: 100 - 140 bar.

Flow cup gun: nozzle 2.5 mm, atomizer air pressure: 2.0 - 3.0 bar.

After drying and intermediate sanding, coat with a water-based or solvent-based lacquer.

Observe the waiting times between coats.

-

Application instructions

-

Check the product’s compatibility, adhesion and sealing effect on the substrate by applying to trial areas.

Do not use on wood impregnated with boron salts.

-

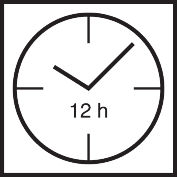

Drying

Longer drying times can improve the sealing effect.

The product’s insulating effect may be impaired if it is diluted too thinly, if the wood is too wet or if the recommended coating sequence, application volumes and drying times are not observed. With water-based coating systems, there is always the residual risk that substances contained in the wood will leach out.

-

Working tools / cleaning

-

Brush with synthetic bristles, foam roller, suitable spraying equipment

Clean tools immediately after use with water.

Ensure that any residue from cleaning is disposed of correctly.

-

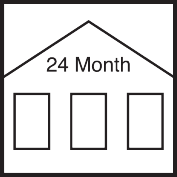

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

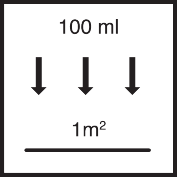

100 ml/m² per coat

2 coats are needed for corrosion protection and to seal off substances in the wood.

-

Application examples

-

Application examples Standards Cleaning Notes Base coat Intermediate coat Topcoat Iron and steel Please refer to BFS leaflet no. 20 The metal must be completely cleaned of rust, rolling skin, scale and welding residues by mechanical means until a shiny metallic surface is visible.

Standard cleanliness grade SA 2.5 (blasting) and ST3 (machining) in accordance with DIN EN ISO 12 944-4. Furthermore, sharp edges and burrs should be rounded. Sealing and Universal Primer Sealing and Universal Primer See

possible

system productsPowder-coated elements

Please refer to BFS leaflet no. 24 Ammonia-based cleaner with abrasive fleece Depending on the powder coating, we recommend creating a test area to check adhesion Sealing and Universal Primer

--- See

possible

system productsRigid PVC Please refer to BFS leaflet no. 22 Ammonia-based cleaner or Thinner & Brush Cleaner with abrasive fleece Depending on the type of PVC and the stress class, we recommend creating a test area to check adhesion Sealing and Universal Primer

--- See

possible

system productsAluminium (non-anodised) Please refer to BFS leaflet no. 6 Ammonia-based cleaner or Thinner & Brush Cleaner with abrasive fleece Depending on the type of aluminium and the stress class, we recommend creating a test area to check adhesion Sealing and Universal Primer

--- See

possible

system productsLoad-bearing old coatings Please refer to BFS leaflet no. 20 Remove all traces of unstable substrates. Only stable, non-chalking substrates may be coated. Depending on the old coating, we recommend creating a test area to check adhesion Sealing and Universal Primer

--- See

possible

system productsZinc and galvanised steel

Please refer to BFS leaflet no. 5 Ammonia-based cleaner or Thinner & Brush Cleaner with abrasive fleece

Depending on the type of zinc and the stress class, we recommend creating a test area to check adhesion

Sealing and Universal Primer

--- See

possible

system productsWood Please refer to BFS leaflet no. 18 Remove all traces of dirt, grease and loose old coatings. Remove loose and torn knots, open resin spots and clean (e.g. with Thinner & Brush Cleaner) Depending on the wood substrate and the stress class, we recommend creating a test area to check the adhesion/sealing effect Wood Preservative Primer* / Wood Impregnation eco

2 x Sealing and Universal Primer See

possible

system products

-

-

General information

-

On planed larch and softwoods with a high resin content, the coating may have reduced adhesion and resistance to weathering. This is especially the case on horizontal year rings, knots and areas of winter growth that are high in resin. Maintenance must be carried out more frequently on these surfaces.

The only remedy for this is pre-weathering or very coarse sanding (P80).

If these wood types are rough-sawn, considerably longer maintenance intervals are to be expected.In the presence of air and water, aluminium forms an oxide layer that can have a negative impact on the product characteristics of coatings. Therefore, when working with aluminium, the coating must be applied immediately after pre-treating the substrate.

Observe the regulations concerning design principles for wood protection.

Do not use on horizontal surfaces without drainage slopes and without edge radius, avoid accumulated moisture.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-