Article No. 687001

Flexible, moisture-reactive 1K PU injection resin, D-I (P)

Product specifications

1C on delivery

Once fully cured

LANG_PK_1K_DICHTE

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Crack injection in concrete according to DIN EN 1504-5

- Classification: U(D1) W(3) (2/3/4*) (8/30) *Only for water-bearing cracks under gravity!

- Moisture level: DP, WT, WF

- Building waterproofing against pressing water

- Sealing of damp and water-bearing cracks

- Caution! Moisture/water must be present

Properties

- Reacts to moisture

- High chemical resistance

- High flank adhesion

- Very high elasticity

-

Preparation

-

Substrate requirements

The flanks of the crack must be dimensionally stable and free from loose parts, sintered layers, oils, grease and other separating substances.

The flanks of the crack must be at least damp.

Pre-wet dry crack flanks.

-

Preparations

Plug the path of the crack if necessary.

Use a suitable packer.

-

-

Application

-

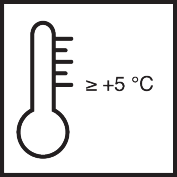

Application requirements

Temperature of the material, air and substrate: min. 5 °C

-

Using suitable injection technology, inject the material from bottom to top.

Remove packer, seal boreholes if necessary.

-

Application instructions

-

Conduct an analysis of the structural condition prior to injection.

Adjust the injection pressure according to the properties of the building component.

Conduct any subsequent injection within the working time.

When injecting into vertical or overhead cracks, tamp the run of the crack.

Remove the skin that forms as a result of reaction with humidity and do not mix in.

When using in large cavities, select a suitable injection quantity based on the component properties on account of the significant increase in the volume of the material.

As a general principle, higher temperatures will reduce and lower temperatures will increase the times stated.

-

-

Working tools / cleaning

-

Injection device, hand lever press, hammer drill

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and splashed material immediately while fresh with V 101.

Take suitable protective and waste disposal measures when cleaning.

-

-

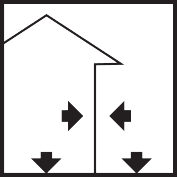

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

- To be determined on a case-by-case basis

- Dependent on the moisture level in the structure, crack width and component thickness

- Approx. 0.1 kg/l void

- Approx. 0.3-0.5 kg/running metre

- Volume increase approx. 25x

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C). Slight deviations from these values may arise if the product is worked with on site.

The actual amount of material needed depends on the size of the void. Proceed based on the results of the building condition analysis.

Remember that surplus material may be needed depending on the application method.Do not allow condensation to form in the injection device.

Once the work is finished, thoroughly empty and clean the injection device.

The current technical regulations must be observed.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

Further information concerning safety during transport, storage and handling as well as on disposal and ecology can be found in the latest Safety Data Sheet.

-