Article No. 061730

Aqueous, hydrophobising and oil-repelling protective impregnation and easy-care treatment

Product specifications

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Makes surfaces easy to clean

- Natural stone kitchen worktops (low levels of soiling)

- Care product for surfaces impregnated with Funcosil OFS

- Mineral building materials

- Floors and walls

Properties

- Repels oil, grease and dirt

- Repels water

- Enables water vapour diffusion

- Alkali-resistant

- Solvent-free

- PFAS-free formulation

-

Preparation

-

Substrate requirements

The substrate must be clean, dust-free and dry.

-

Preparations

Any construction defects such as cracks, cracked joints, defective connections, rising damp and hygroscopic moisture must be remedied in advance.

-

-

Application

-

Apply the impregnation agent evenly. If it is fully absorbed, repeat the process while wet. Remove excess material with e.g. a lint-free cotton cloth after a maximum of 10 minutes.

Cleaning and care - for maintenance cleaning on treated surfaces, use warm water plus approx. 1.5 - 2.0% product (one cup of product in 10 l of cleaning water).

Refresh treated surfaces using the material in undiluted form.

-

Working tools / cleaning

-

Non-corroding low-pressure conveying and spraying equipment, liquid pumps, paintbrush, flat brush, lamb's wool roller, sponge, cloth and mop

-

Tools must be clean and dry.

Clean tools with water after use and before any lengthy interruptions to work.

-

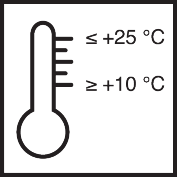

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

Use the contents of open containers as quickly as possible.

-

Usage

-

Brick: approx. 0.1 - 0.5 l/m²

Sand-lime brick: approx. 0.1 - 0.6 l/m²

Natural stone: approx. 0.4 - 1.0 l/m²

Terracotta: approx. 0.2 - 0.8 l/m²

Concrete slabs: approx. 0.1 - 0.5 l/m² -

Apply to a large enough trial surface (1-2 m²) to determine the precise amount of impregnation agent required.

The effectiveness of the impregnation can be checked on a trial area after a sufficient waiting time has passed.

-

General information

-

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

Water must not be allowed to penetrate behind the hydrophobized zone.

Please note: in the case of marble and other types of stone that have polished surfaces and poor absorption capacity and are sensitive to acids, as well as fine stoneware of all kinds, the suitability must be tested in advance (uniform wetting, absorption capacity, changes in gloss etc.). This is also advisable on surfaces that have previously been treated with other products.

The level of absorption is crucial for the impregnation agent to work at its best. This depends on the respective pore volume and moisture content of the building material.

Carry out a quantitative analysis of aggressive salts if there are any salts present that could damage building materials.

High concentrations of harmful salts can cause major structural damage that impregnation cannot prevent.

Residue (e.g. surfactants, wax) from previous cleaning measures can have adverse effects on the treatment and must therefore be completely removed.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-